Fabbing: LinkedIn Learning tutorials

Video tutorials

LinkedIn Learning (formerly known as Lynda.com) is a subscription-based video tutorial platform that delivers carefully curated video courses on a variety of software. Many schools offer an institutionally-based subscription to their academic community. If you use this wiki for school, check into it. For personal use, LIL can run up to nearly $40 per month for a personal subscription, so take advantage of an institutional plan!

Tutorials for 2D>3D | Line to plane

Do the following for Autodesk Fusion 360 and Laser Cutting:

STEP 1 | Create an account with Autodesk for Fusion 360, the cloud-based CAD-CAM software:

- If you are in school take advantage of the individual Education license that allows you to use the software in our lab, and also to download and use it for free on a personal machine with an EDU license.

- If you see an indication of a trial expiration when you open Fusion 360, you have requested the WRONG license! Please contact your local campus IT office to resolve this issue.

STEP 2 | Use an institutional LinkedIn Learning subscription if your school offers one. At my school:

STEP 3 | Do the tutorials:

Focus on the following chapters:

- Introduction

- 1. User Interface

- 4. Organic Sculpting

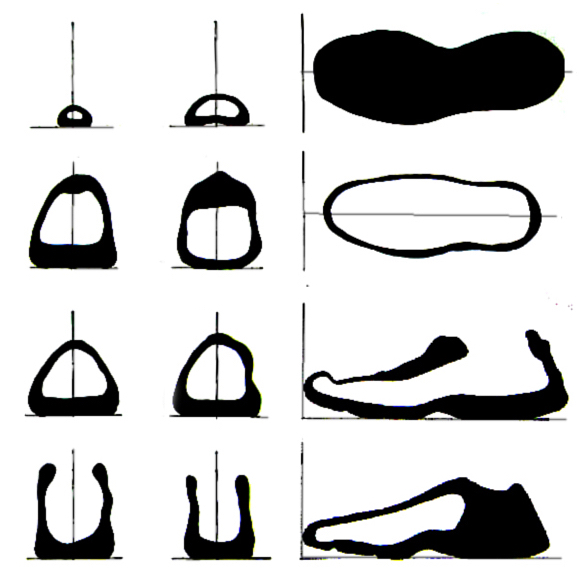

You are creating the bike seat model for presentation on your process journal or blog.

Focus on the following chapter and headings:

- 4. Design Considerations

- Cutting an interlocking form

- Process limitations

- Formatting your art

This is a watch-and-learn experience to apply in your actual project. No product is expected here.

The Fusion 360 Bike Seat model contains a highly useful workflow that will make the development of your project design go more quickly. It is STRONGLY RECOMMENDED that you work alongside the tutorial in Fusion 360 at least once. The time notes suggest it will take less than 2 hours to get through the entire title.

Tutorials for 3D | Plane to volume

Do the following for Meshmixer, 3D Printing, and 3D Scanning:

STEP 1 | If you already have access to Meshmixer go to the next step. If not, download and install for your preferred device:

- If you cannot access the link above, do a browser search for “Meshmixer download.”

- Meshmixer is no longer supported by Autodesk, which claims Meshmixer functionality will be integrated with Fusion 360. Keep your eye on updates here and in the Autodesk chatrooms.

STEP 2 | Use an institutional LinkedIn Learning subscription if your school offers one. At my school:

STEP 3 | Do the tutorials:

Focus on the following chapters and headings:

- 2. 3D Printing

- Using 3D printing software

- Using an FDM-style 3D Printer

- 7. Understanding 3D Scanning

- Using a laser scanner

There are no products associated with these very brief tutorials.

Focus on the following chapter

- 1. Overview | See all titles

- 2. Evaluating and Fixing

- Using Meshmixer’s automated fixing techniques

- When automated fixing isn’t enough: Remeshing

- 3. Working with Multiple Objects in Meshmixer

- Why do separate bodies matter? Booleans and exporting

- Booleans revisited and defined

There are no downloadables for this tutorial: use the importable Bunny mesh.

Optional | If you are an advanced modeler and wish to incorporate a working axle or hinge:

There is no requirement to provide documentation for this optional work.

Tutorials for 3D>4D | Implied motion

Do the following for Autodesk Fusion 360 and Laser Cutting:

STEP 1 | If you already signed on for an Autodesk license, skip this step… if not, create an account:

STEP 2 | Use an institutional LinkedIn Learning subscription if your school offers one. At my school:

STEP 3 | Do the tutorials:

Focus on the following chapter:

- 2. Sketching

We only need Chapter 2, the elements of the Strandbeest hinge. Chapter 3 Geometric Modeling is optional for advanced modelers, but the skills learned there are not essential for our design work.

Focus on the following chapter and headings:

- 3. Machining

- Understanding how a computer-numerical-control (CNC) mill is set up

- Working with computer-aided manufacturing (CAM) software for part programming

- Exploring CNC prototyping services

This is a watch-and-learn experience to apply in your actual project. No product is expected here.

Beyond LinkedIn Learning: G-code and driver software

Use the following to learn about our CNC software packages:

Focus on Videos:

- Importing Files | 1:10

- Stock Setup | 1:05

- Setting Zero | 1:04

- Tool Library | 1:03

- Global Options | 1:45

- Roughing | 2:05

- Finishing | 1:03

Carbide Motion runs the CNC router using the G-code made in MeshCam. This 8-minute video will familiarize you with the interface.

There are no files or objects produced with these g-code and driver tutorials.

It is STRONGLY RECOMMENDED that you work alongside the tutorial in Fusion 360 at least once. The time notes suggest Chapter 2 for parametric extrusion is just over one-half hour.